LED, as the fourth generation lighting,

with characteristics of energy conversation, environmental, longevity,

compact, is now widely used in various fields such as lighting.

displaying,piloting, decoration, backlight and so on.

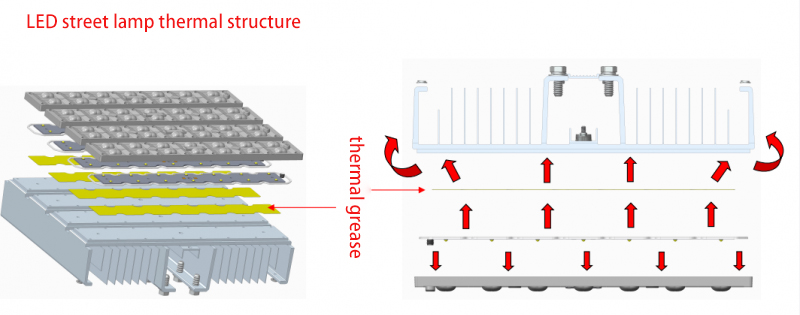

At present , LED electro-optic conversion

efficiency is only about 20-30%,about other 70% energy is turned into

heat.That is why there is urgent desire in LED heat dissipation.

Electrons combining holes can only

engender approximate 90% photons. Current leakage reduces the

recombination efficiency in PN region, the leakage current multiplied by

the voltage is the power of this part,which is converted into heat.

Not like 15lm/w incandescent lamp

converting almost all electric into light and eliminating the heat

dissipation problem,only 30% of the internal photons of LED can be

emitted to the chip and others finally converted into heat.

LED chip will generate extremely

excessive heat in limited space, surmount its heat capacity, this

requires efficient heat conduction avoid junction temperature

occurrence.

Continuous high temperature of LED lamp

caused by working chip, will impact on its service life and stability

seriously.the lower the luminous rate brings the higher temperature.

This confusing attracts more and more

attention Shenzhen Opute Electronic technology Co.,LTD has successively

developed allround-performance ,user-friendly targeted products for LED

market.

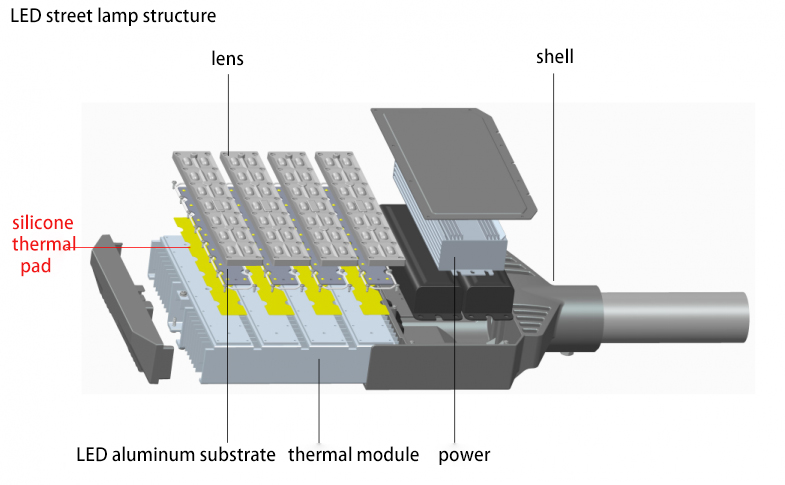

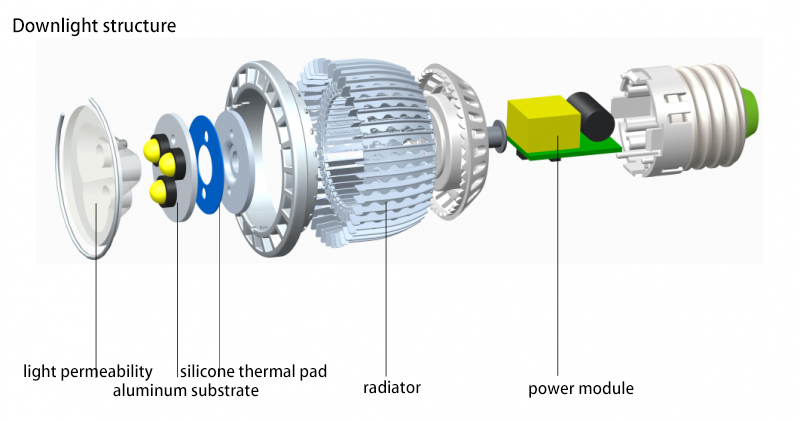

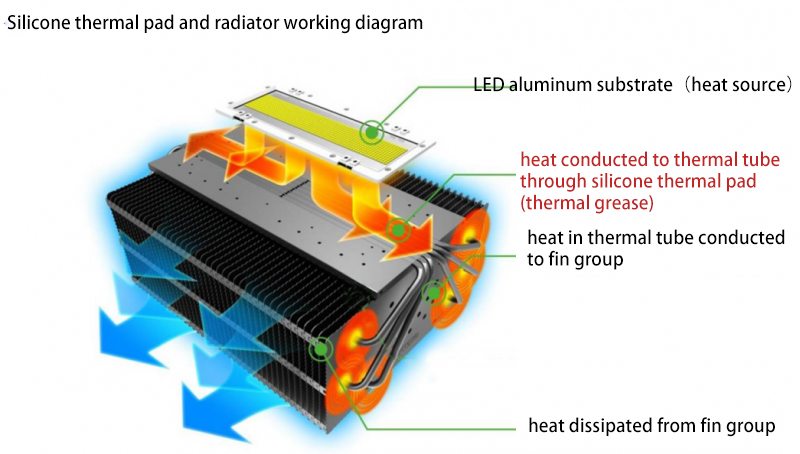

In order to satisfying mutiple scenarios users, Opute silicone thermal pad series have various structure, besides taking glass fiber and silicon

fabric as reinforcement carrier, designing both single and double sided

adhesive to fasten PCB and radiator.

CN >

CN >